📊 KATOY Welding Machine Transformers

Katoy Transformers used in welding machines are specially designed to convert standard electrical power into the high-current, low-voltage output required for welding. These transformers are built to handle extreme electrical loads, deliver precise control, and operate in rugged environments.

Katoy manufacturers Industrial Welding Machine Transformers to any specification required for your application.

🔧 What Welding Transformers Do

At the core, a welding transformer changes:

- High voltage / low current (from the grid) ➝ Low voltage / high current

- This high current is essential to produce the intense heat needed to melt and fuse metal in arc welding.

⚙️ Key Characteristics

1. Step-Down Voltage, Step-Up Current

- Grid power (e.g. 220V or 440V) is stepped down to 20–80 volts, while current is stepped up to hundreds of amps.

- This makes them ideal for arc welding methods like SMAW (stick welding) and AC TIG.

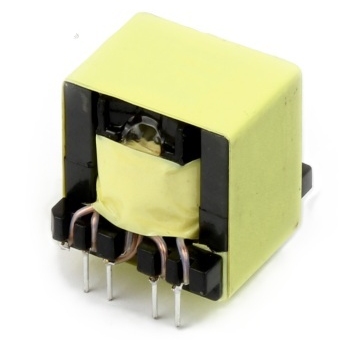

2. Robust Coil Design

- Primary winding connects to incoming power.

- Secondary winding delivers high-current output to the welding torch/electrode.

- Made with thick copper wire and heavy insulation to handle the high current and resist shorting.

3. Voltage & Current Control

- Many welding transformers allow for output adjustment, using:

- Taps on the secondary coil

- Movable core shunts

- Reactors or inductors in the circuit

- This allows the operator to tune the arc based on:

- Material thickness

- Type of metal

- Type of electrode

4. AC vs. DC Output

- Basic welding transformers output AC (Alternating Current).

- Some machines add a rectifier to convert the output to DC (Direct Current), which is preferred for:

- More stable arcs

- Less spatter

- Better performance on thin metals and specialty alloys

🏭 Common Welding Transformer Types

| Transformer Type | Description | Use Case |

|---|---|---|

| Conventional EI-Core | Large laminated steel core with wound copper coils | Stick welders, basic AC machines |

| Reactor Transformer | Includes inductors to stabilize current flow | Smoother arc performance |

| High-Frequency Transformer | Used in inverter-based welders with compact design | TIG, MIG, portable welders |

| Toroidal Transformer | More compact, low EMI | High-efficiency or compact machines (less common) |

✅ What Makes Welding Transformers Unique?

- High current capacity for fusion-level heat

- Thermal durability under continuous load

- Precise adjustability for weld control

- Isolation between power supply and output

- Rugged construction for tough industrial environments

🔩 Applications

- Manual Arc Welding (SMAW)

- Gas Tungsten Arc Welding (AC TIG)

- Industrial and structural steel welding

- Heavy equipment repair and fabrication